2024 IBEX Innovation Award Interview with Supersede

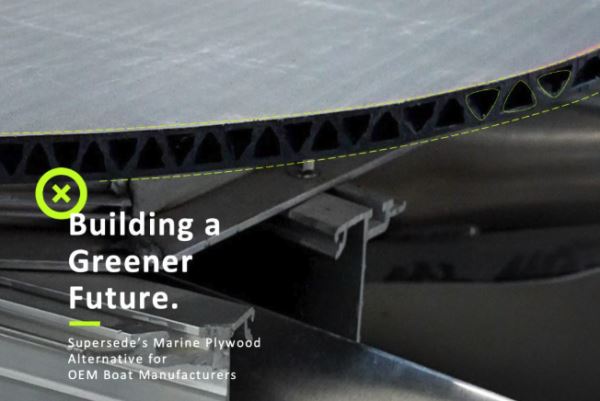

What would it take to disrupt a $31 billion legacy market? While marine-grade plywood has been the boatbuilding go-to material for decades, boat manufacturers know more than anyone the challenges of working with wood. Supersede’s marine plywood alternative — an engineered, extruded sheet crafted from plastic waste — tackles the challenges of working with wood and prioritizes strength, fastener retention, and cost-efficiency without adding weight. Supersede Marine Board addresses the gap in the market for high-performance, eco-friendly, and cost-effective alternatives in boatbuilding.

One of the biggest challenges Supersede faced during the development process was creating a product within the same geometrical constraints as standard thickness products, said Supersede Co-founder and CEO Sean Petterson. “This challenge then boiled into sub-challenges of maintaining cost, weight, recyclability (our core tenet), and performance. We overcame these challenges and we’re proud of our commitment to sustainability.”

What problem was the Supersede Marine Board designed to solve?

The Supersede Marine Board is designed to solve numerous challenges associated with traditional marine grade plywood. For instance, traditional plywood prices are still one-third higher than they were in 2019, following pandemic-related supply chain challenges. Also, boat manufacturers are increasingly facing a rise in plywood warp, rot, splinter, and performance issues due to changes in moisture levels. Marine grade plywood is also processed using harmful chemicals that are known to pose possible health, safety, and environmental hazards. While marine grade plywood has been in use for decades, the unreliability of its supply chain, its non-durability, and its potential risk to human and environmental health makes the plywood market—worth $31.5B in the United States alone—ripe for transformation.

Who is the target market for Supersede Marine Board?

We are currently addressing the boatbuilding and RV manufacturing markets. We also plan to make our solution available for the construction industry and manufacturers of trailer tractors and modular homes.

Who is currently using Supersede Marine Board? What feedback have you received?

Supersede is a new company that has been operating in stealth mode for the past year. Since opening our plant in Phoenix, we’ve been rigorously testing Supersede Marine Board with several prominent boat and RV brands. We’re excited to share details about our launch partners next year, and we’re thrilled with the feedback so far, as the Supersede board has consistently exceeded expectations.

Manufacturers seeking a reliable alternative to wood prioritize strength, fastener retention, and cost-efficiency without adding weight, and Supersede has checked all those boxes. The market has long needed a durable, sustainable replacement for marine grade plywood, and our board delivers on every front.

Our partners appreciate that Supersede board works seamlessly with their existing production lines, requiring no special handling. Unlike some alternatives, there’s no need for through-bolting or additional processes. Supersede even simplifies assembly: Each board is 100 percent waterproof. There’s no need for finishing or waterproofing which saves significant time and resources in production.

What kind of boats is Supersede Marine Board being used on?

What kind of boats is Supersede Marine Board being used on?

Pontoon boats are a natural fit for Supersede Marine Board. The board’s stiffness, strong fastener retention, and adherence capabilities create new possibilities for design while contributing to a more durable, long-lasting pontoon build. However, Supersede’s applications extend well beyond pontoons. Our board is ideal for any flooring needs, as well as transoms, stringers, cabinetry, and virtually any other structural component in boat construction where wood is traditionally used. Supersede provides a robust, waterproof alternative that enhances both performance and longevity across a wide range of boat types.

How has it changed the boatbuilding process?

Supersede Marine Board has made boatbuilding cleaner, greener, and more efficient. While the overall process is similar to building with plywood, Supersede simplifies and improves many steps. With plywood, additional processes are often required to achieve a smooth finish or to seal fastener penetrations with fillers like Bondo to maintain waterproofing. Supersede, being a dense and 100 percent waterproof material, eliminates these issues. Its density prevents overdriving fasteners, and any penetrations from fasteners do not compromise its waterproof integrity. Plus, Supersede boards arrive perfectly smooth and ready to install, eliminating the need for sanding.

The aesthetic quality of Supersede is another advantage. While wood is typically covered, Supersede has an attractive finish that can be left exposed—for instance, on the underside of a double-decker pontoon or as the backing of a seat. For large customer orders, we offer custom color options, achieved through our dual extrusion technology, and a variety of surface finishes, providing boards that are not only functional but also visually appealing.

Supersede also promotes a cleaner and safer work environment. Unlike wood and traditional wood alternatives, which release harmful dust particles when cut or machined, Supersede does not, making it a safer choice for employees and reducing dust in manufacturing facilities.

Additionally, we’re proud of our commitment to sustainability. Supersede offcuts are fully recyclable, and we offer a buy-back program where we purchase scrap from our customers, which we recycle into new products, supporting zero-waste goals and creating a truly circular solution for marine construction.

Why will boat builders choose the Supersede Marine Board over what they’re using?

Why will boat builders choose the Supersede Marine Board over what they’re using?

Boat manufacturers and their insurers have more experience than almost anyone with the headaches of plywood—from the persistent challenges associated with inconsistent performance, warping and splinters, to extensive maintenance and high costs. At Supersede, we have created the first modern breakthrough addressing these issues with the Supersede Marine Board, a true 1:1 replacement to marine-grade plywood that has all the attributes boat manufacturers look for: a durable, reliable, and affordable solution that is non-hazardous, environmentally sustainable, and always consistent. This isn’t just an upgrade to the legacy plywood industry—it’s a long overdue leap forward.

Are the advanced materials and design of Supersede indicative of trends in boatbuilding? Is it in response to larger trends in boatbuilding?

Supersede’s materials are addressing a clear gap in the market for high-performance, eco-friendly, and cost-effective alternatives in boatbuilding. At Supersede, our mission is to make a positive environmental impact, and while our materials offer superior performance compared to industry standards, we aim to price them competitively. This approach enables us to reach more manufacturers and ultimately contributes to our goal of reducing plastic waste and conserving trees that would otherwise be harvested for marine applications.

We believe that this should indeed be a trend in the industry. While everyone seeks materials that are cheaper, better, and faster, it’s essential to consider the environmental impact and long-term value for consumers. Boatbuilding is an ideal industry to showcase technological advancements while also demonstrating environmental stewardship. Supersede’s solution aligns with both goals, creating a win-win scenario that we hope will inspire more companies to adopt sustainable materials and practices.

What obstacles arose during the R&D process?

The biggest challenge that Supersede faced during the R&D process is creating an equivalent performing product within the same geometrical constraints as standard thickness products. This challenge then boiled down to four sub-challenges of maintaining cost, weight, recyclability (our core tenet), and performance. We overcame this challenge in a few distinct ways, namely creating an intensive benchmark catalog of performance across all current marine boards, including characterizing the high variation amongst wood products, by physical testing, customer feedback, trial builds, and real world testing. Using that benchmark catalog as a design matrix, we drove all engineering decisions and development through a constant feedback loop of CAD design, FEA simulation, manufacturing feasibility, and costing exercises to wind up at our Marine Board.

What impact do you see Supersede Marine Board having on the boating industry?

There has long been demand in the boatbuilding industry for manufacturing solutions that are affordable, effective, non-toxic, and environmentally sustainable. With the Supersede Marine Board, the boatbuilding industry now has a unique, innovative solution that addresses numerous longstanding pain points. We anticipate that more boatbuilders will increasingly recognize the value of Supersede Marine Board and replace traditional marine-grade plywood with Supersede in their boatbuilding processes.

What plans are in place for the future of Supersede Marine Board?

What plans are in place for the future of Supersede Marine Board?

Looking ahead, Supersede’s plans include partnering with more manufacturers to transform their waste into valuable resources, driving a more circular economy within the marine and manufacturing industries. We collaborate closely with our partners to develop unique, sustainable solutions that enhance product performance and longevity. Our R&D efforts will continue to focus on innovative tooling and designs to expand Supersede’s applications across a broader range of industries.

We’re also aiming to address larger waste streams and enter new markets, alongside advancing material innovations. Our future product line will feature an expanded range of laminated options, surface finishes, and customizable solutions to meet the specific needs of our customers. These enhancements will provide a drop-in replacement that’s not only cost-effective but also durable, environmentally friendly, and beneficial for end consumers. Supersede is committed to pushing boundaries in material science to deliver better, longer-lasting solutions for our customers and the planet.